Columbia University - McIver Lab

New York, NY

Department of Physics

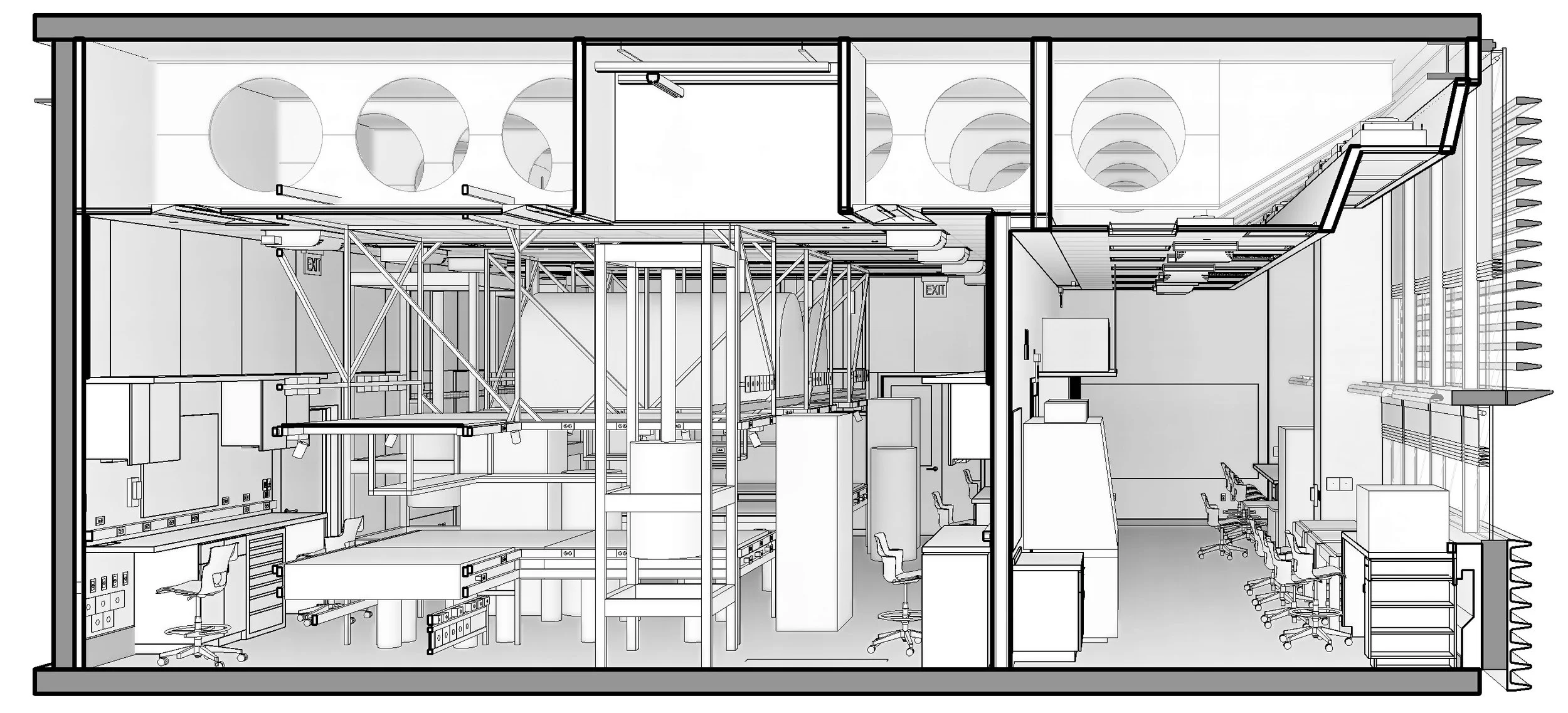

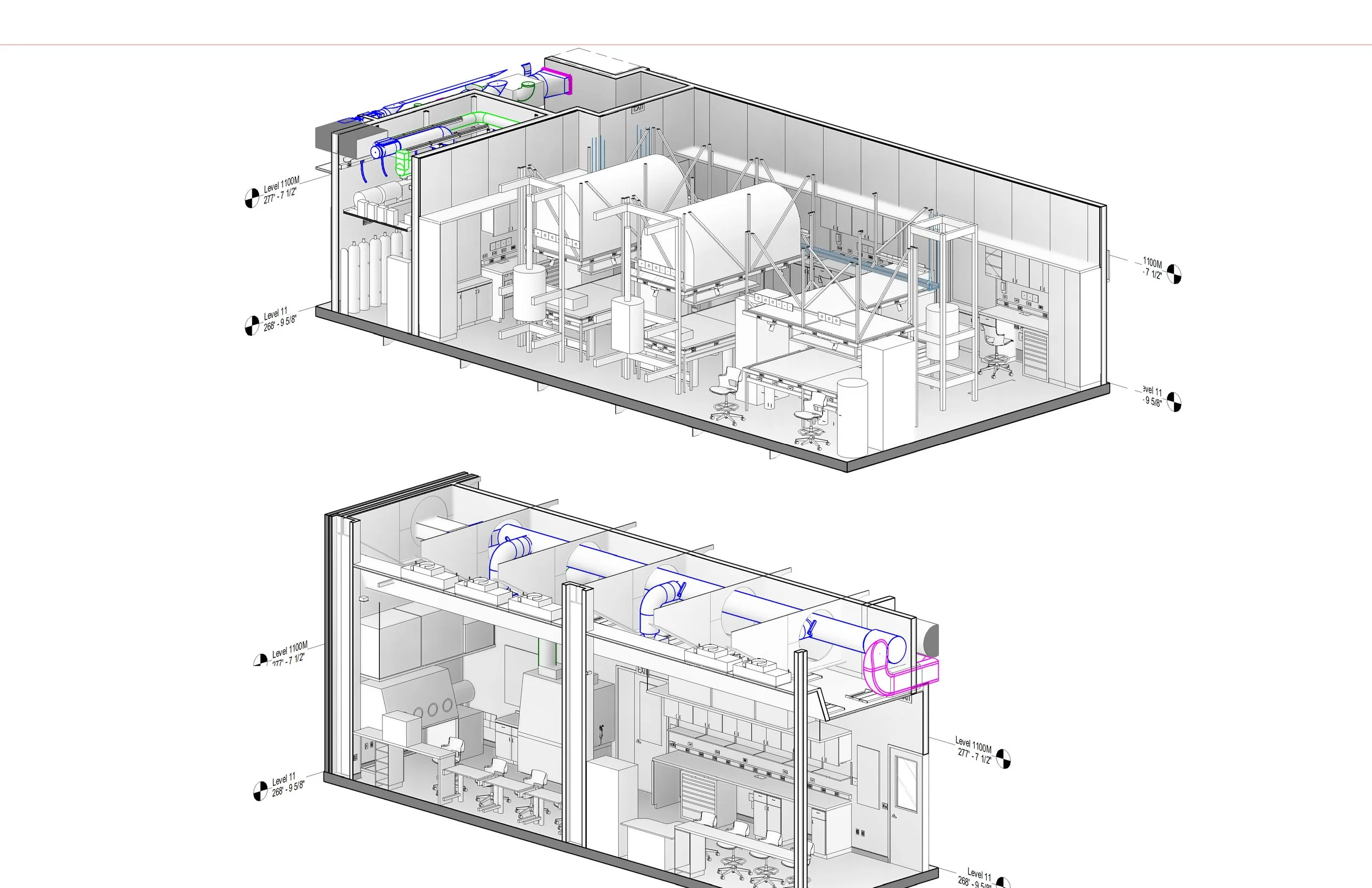

As part of an on-call contract with Columbia University, Spacesmith designed a research laboratory for Assistant Professor of Physics James McIver. Located in Columbia’s Northwest Corner Building, the new suite includes four zones: a vestibule, pump room, laser lab, and prep lab. The 2,500 sf space required specific MEP systems and equipment, located strategically to optimize workflow, collaboration, safety, and maintenance.

Our team began by reviewing equipment and adjacency requirements. The detailed MEP specifications posed the biggest challenge; we collaborated closely with our consultants to locate all specialty items within the building’s existing structural and mechanical conditions. The resulting space meets all programming needs while adhering to Columbia University’s strict design guidelines.

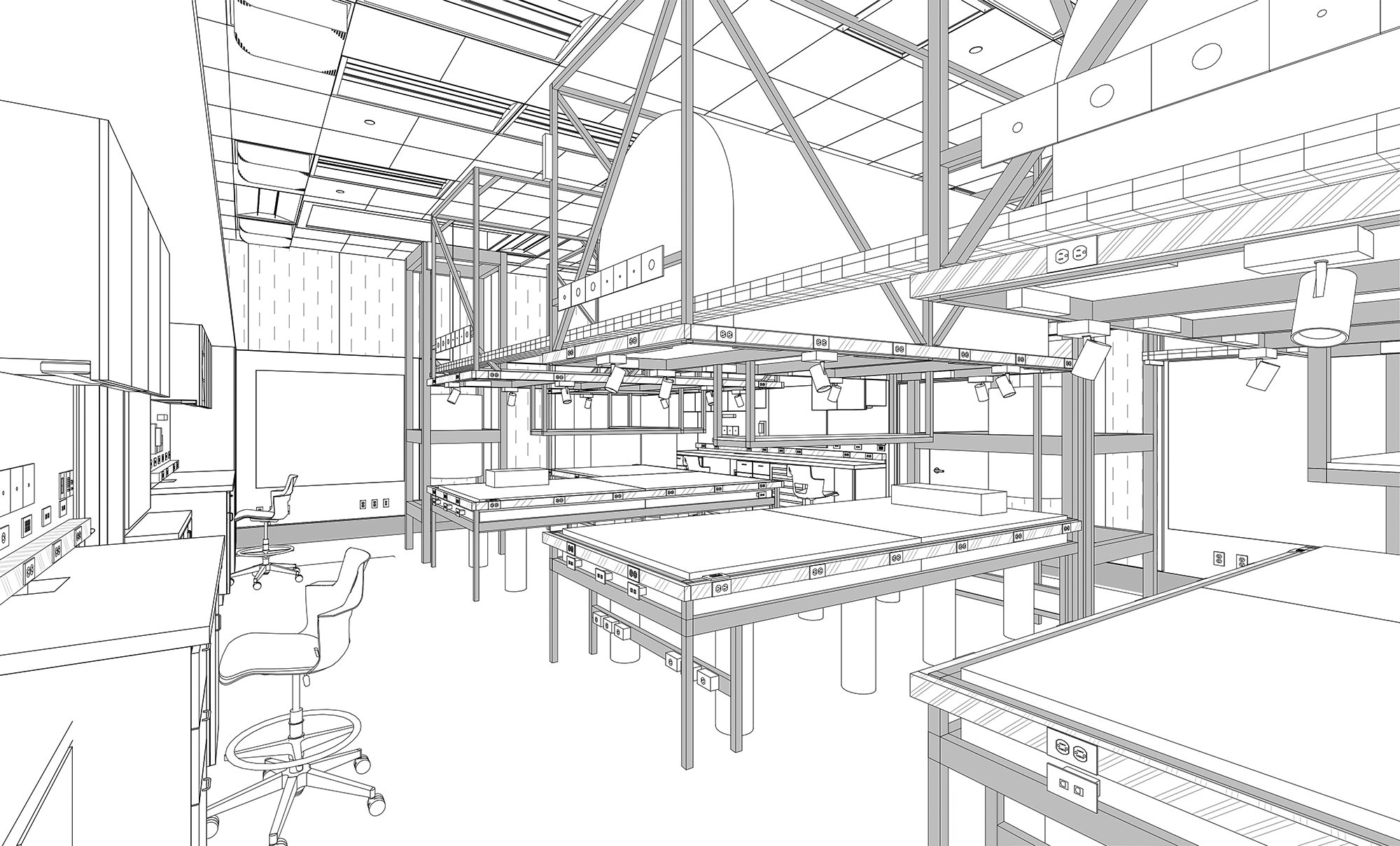

Upon entering the lab, researchers pass through a vestibule outfitted with ceiling-height, solvent-resistant cabinetry and shelving to store protective gear and whiteboards. The vestibule leads to the pump room, which supplies the laser lab with all gas, electrical, and vacuum lines needed to conduct experiments. Within the walls, a robust framing and insulation system plus resilient sound isolation clips minimize vibrations and sound. Beyond the pump room, the laser lab holds three optical tables, each with two experimental setups.

These have extensive power and plumbing requirements that must be spaced throughout the lab for flexibility. All lines serving this room, including those for cooling water, compressed air, and vacuum, run parallel to one another and connect to centralized, wall-mounted outlet blocks in key locations. All cryostat compressors, chillers, and controllers are positioned in the acoustically isolated pump room and fed through ceiling channels into the laser lab. Perforated acoustic panels provide further noise mitigation.

Many of the tasks performed require a clean room environment. Ceilings in both the prep and laser labs are clean room grade to reduce air leakage, improve air quality, and prevent noise transfer. Furthermore, each area demands specific humidity and temperature stability.

All countertops are solvent resistant and in a color that contrasts with the scientists’ tools, many of which are small and would otherwise be difficult to locate. All millwork is seamless and airtight to protect from dust. The flooring and baseboards are designed to manage the movement and placement of large equipment. Our team upheld the integrity of the cryostats’ magnetic fields by specifying non-ferrous materials for all plumbing, lighting, and outlets.